LEC undertook finite element modelling, analyses and design verification of a drum conditioner for a lithium plant in Australia, which included:

• Design code compliance checks in accordance with AS 3990

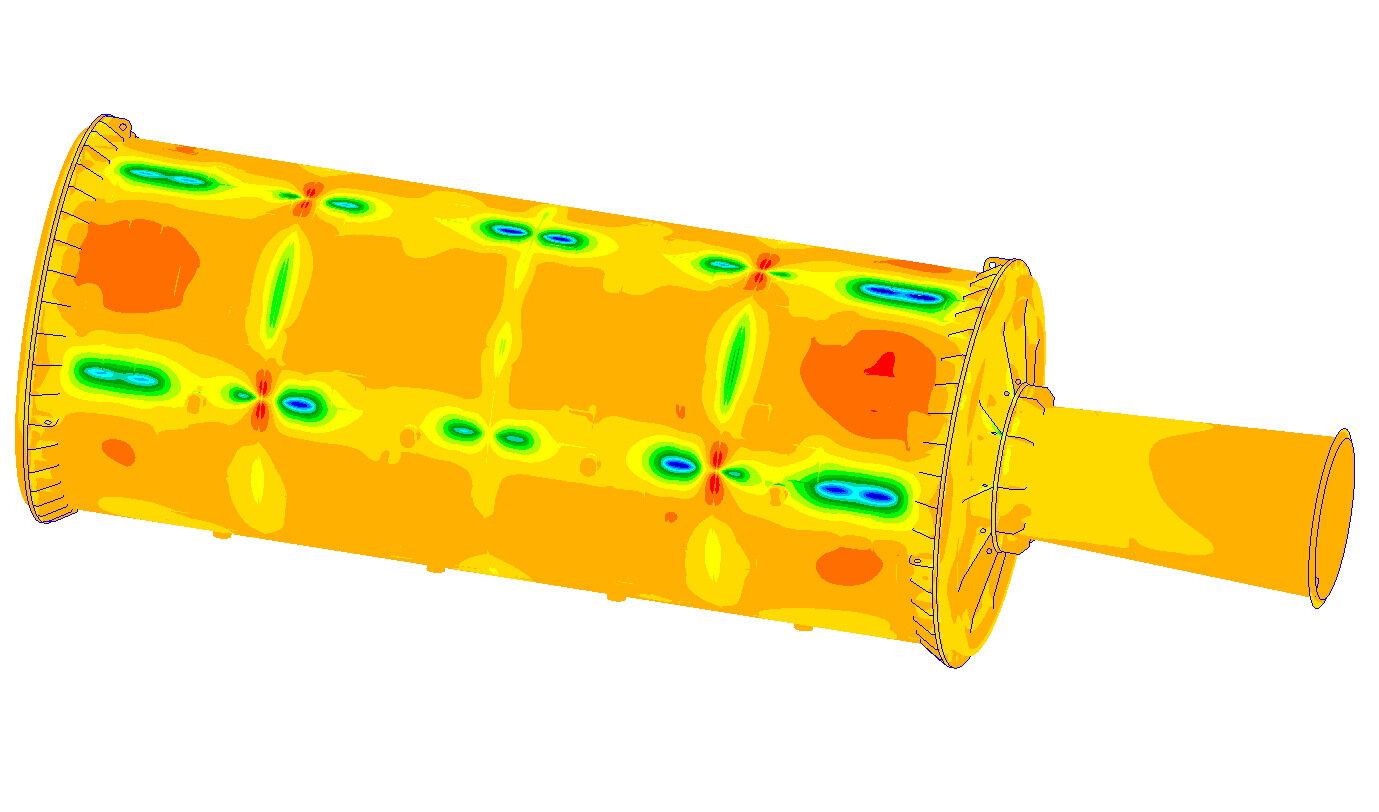

• Buckling analysis using MSC.Nastran

• Natural frequency analysis using MSC.Nastran

• Fatigue endurance limit calculations in accordance with the requirements of BS 7608

The three-dimensional geometric model was discretised using predominantly MSC Nastran’s QUAD4 plate elements (four-noded quadrilateral isoparametric element) and where necessary TRIA3 (three-noded isoparametric triangular elements). MSC Nastran’s HEXA (eight-noded isoparametric solid elements), PENTA (six-noded isoparametric solid elements) and TETRA (four-noded isoparametric solid elements) were used locally to model the tyre support region closer to the exit end diaphragm to simulate the weld details for fatigue assessment. Fine mesh was adopted in the regions where fatigue assessment was required.

As a result, a design verification report was prepared by LEC containing proposed structural modifications for compliance with the applicable codes and standards.