LEC have been a key technical advisor to Roy Hill throughout their ongoing heavy haul rail bridge bearing replacement program, from feasibility desktop studies through to advanced finite element analysis and bearing replacement.

DESKTOP STUDY OF HEAVY HAUL RAIL BRIDGES

FOCUSING QUESTION

Would it be feasible for the existing rail bridges to withstand an increased axle load and thus enable Roy Hill to increase their rail haulage capacity whilst utilising their existing infrastructure?

THE SOLUTION

LEC undertook a desktop study of three selected bridge spans to determine the maximum load carrying capacity of the existing waterway and overpass steel girder rail bridges along Roy Hill’s mine-to-port rail corridor. Design checks of the main bridge components were carried out for strength (i.e. bending & shear) and serviceability.

THE LEC ADVANTAGE

Based on the outcome of the desktop study, LEC were able to advise Roy Hill of several opportunities that could be explored to increase the axle load on the bridges, such as detailed assessment using finite element analysis (FEA), site deflection & strain gauge measurements to determine the actual Dynamic Load Allowance (DLA), and de-rating of the bridge design load factors.

DETAILED ANALYSIS OF HEAVY HAUL RAIL BRIDGES

FOCUSING QUESTION

Determination of the actual Dynamic Load Allowance (DLA) for selected heavy haul rail bridges.

THE SOLUTION

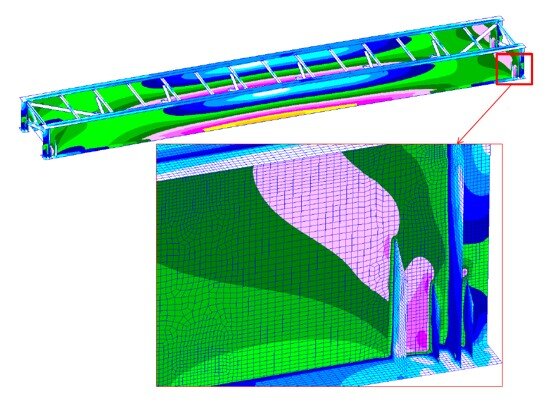

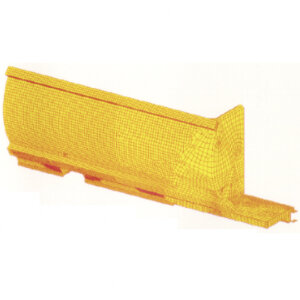

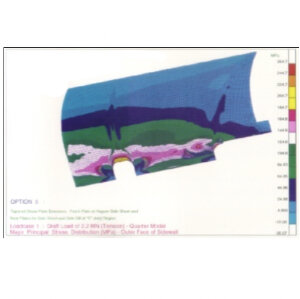

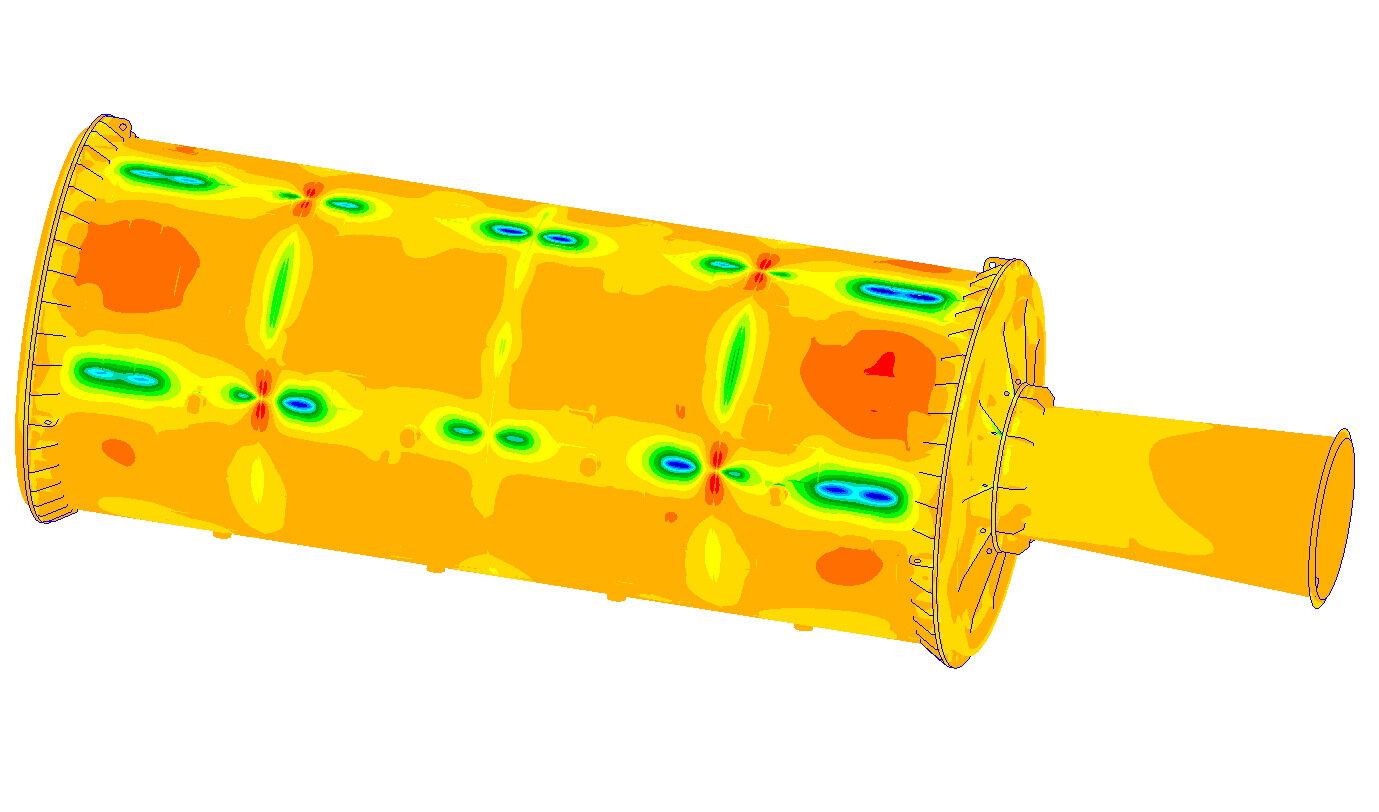

Detailed finite element analysis (FEA) was undertaken by LEC to obtain analytical stress results, which were then compared with on-site strain gauge measurements obtained by Roy Hill’s sub-contractor. This enabled LEC to determine an actual DLA for these bridges.

THE LEC ADVANTAGE

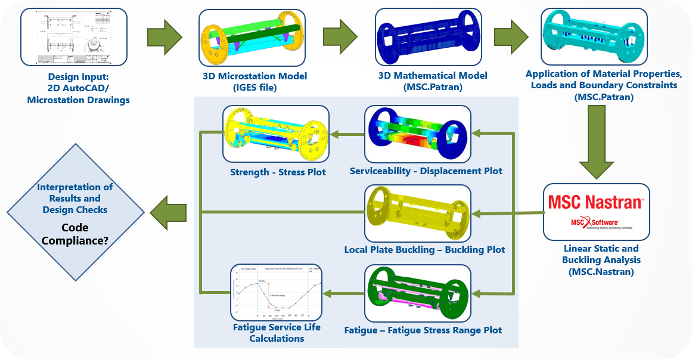

A detailed three-dimensional finite element model of the rail bridges was created by LEC in MSC.FEA using predominantly QUAD4 plate elements (four noded quadrilateral isoparametric element) and HEXA elements (eight-noded brick elements) were used to model the concrete deck. MSC.FEA is a state-of-the-art finite element analysis software package which is well-suited to this type of application.

VISUAL INSPECTION OF HEAVY HAUL RAIL BRIDGE BEARINGS

FOCUSING QUESTION

Roy Hill’s rail line has 11 steel girder rail bridges that form part of the vital link between their mine operations and port export facility, and their safe operation is reliant on the condition of the bridge bearings.

THE SOLUTION

Periodic visual inspections of the bridge bearings were undertaken by LEC to monitor the deterioration rate of the bearing by means of measuring the vertical gap between the upper and lower half of the bearing.

THE LEC ADVANTAGE

The team at LEC were able to provide recommendations based on the periodic measurement data. This allowed Roy Hill to prioritise the bearing replacement programme accordingly.

BRIDGE BEARING DESIGN REVIEW

FOCUSING QUESTION

Roy Hill are replacing the existing elastomeric pot bearings with spherical bearings and the technical aspects of this change need to be fully understood to ensure safe & reliable operation.

THE SOLUTION

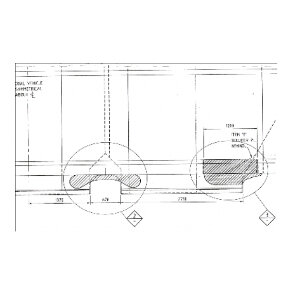

LEC carried out a technical review of the new spherical bearing design, including reviewing the design criteria, design loads & parameters and undertaking structural design checks (such as bolt shear capacity & weld design calculations).

THE LEC ADVANTAGE

During the design review, LEC identified some anomalies in the design loads which were able to be resolved with the original bridge designer and the new bearing supplier. LEC’s dimensional reviews, based on both documentation and site measurements, ensured the new spherical bearings will fit the existing bolt arrangements.

TECHNICAL ASSISTANCE DURING BEARING CHANGEOUT

FOCUSING QUESTION

To minimise disruption to heavy haul rail operations, the bearing changeouts were scheduled during tight shutdown windows.

THE SOLUTION

LEC provided on-site technical support for the bearing changeouts to enable quick resolution of any technical queries.

THE LEC ADVANTAGE

By collaborating with Roy Hill and their sub-contractors, LEC were able to ensure the bearing changeouts occurred on schedule and in accordance with the design intent.

SUMMARY OF SERVICES PROVIDED BY LEC TO ROY HILL

Structural Integrity Assessment

Advanced Finite Element Analysis

Site Inspections of Existing Bearings and Dimensional Measurements

Independent Review of the New Bearing Design

Technical Assistance during the Installation of the New Bearings