Consistent fatigue cracks were observed in a number of coal wagons, which had resulted in loss of revenue for the rail operator. Structural modification of the wagon body structure was required to prevent the crack from re-appearing. The main challenge on this project was to develop an effective solution while minimising the increase in wagon tare mass. Any increase in the ore wagon weight would reduce their payload and the associated revenue.

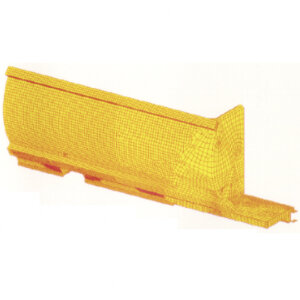

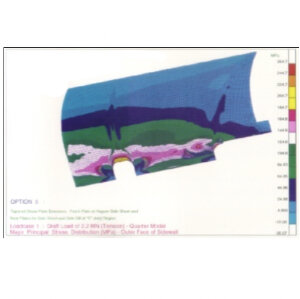

As part of the design process, a finite element model of the wagon was created. The model incorporated sufficient details to reasonably predict the location and magnitude of stress concentrations and hence locations where fatigue cracking may initiate. Fatigue analysis was carried out in accordance with the recommendations given by the Association of American Railroads (AAR), Fatigue Design of New Freight Cars. The results from this analysis were in close agreement with the locations of the existing cracks.

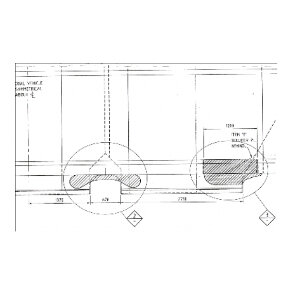

Based on this assessment, a local structural strengthening solution was developed to effectively reduce the fatigue stress. The geometry of the local strengthening was optimised to minimise the weight and for ease of installation. The proposed structural modifications (<1% of the wagon tare mass) have since been successfully implemented and have extended the service life of the wagons by at least 15 years.